Key Factors to Consider When Selecting Steel I-Beams for Commercial Construction

The structural integrity of a building depends heavily on the quality and appropriateness of its supporting elements. Among these, steel I-beams stand out as critical components that provide the necessary strength and stability required for modern commercial structures. As the industry leader in steel products, Intsel Steel (formerly Bushwick Metals) has supplied premium structural steel for countless commercial projects, giving us unique insights into proper I-beam selection.

Steel I-Beams: The Foundation of Commercial Construction

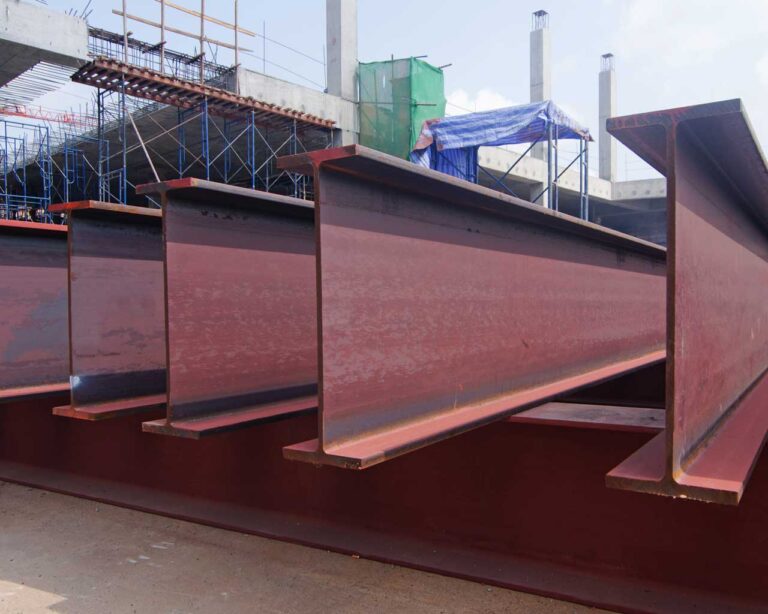

Steel I-beams, named for their distinctive “I” cross-sectional shape, consist of two horizontal elements (flanges) connected by a vertical component (web). This design efficiently distributes loads while minimizing the amount of material required, making I-beams both economical and structurally sound for commercial applications.

The widespread use of steel I-beams in commercial construction stems from several inherent advantages:

- Superior strength-to-weight ratio compared to other building materials

- Excellent load-bearing capacity for both vertical and horizontal forces

- Dimensional stability under varying temperature conditions

- Consistent quality through standardized manufacturing processes

- Versatility across numerous commercial applications

Critical Factors When Selecting Steel I-Beams

1. Load Requirements and Structural Analysis

The primary consideration when selecting steel I-beams is understanding the specific load requirements your commercial structure must support.

This includes:

- Dead loads: The permanent weight of the structure itself

- Live loads: Temporary or variable weights (occupants, furniture, equipment)

- Environmental loads: Forces from wind, snow, seismic activity

- Dynamic loads: Moving or vibrating machinery

A thorough structural analysis by qualified engineers will determine the minimum strength requirements for your I-beams. Intsel Steel’s engineering support team can help interpret these specifications to ensure you select I-beams that meet or exceed these requirements.

2. Steel I-Beam Material Grade and Strength Properties

Steel I-beams come in various grades, each offering different mechanical properties suited to specific applications:

- A36: A common carbon steel with a minimum yield strength of 36,000 psi, suitable for many general commercial applications

- A572 Grade 50: High-strength, low-alloy steel with a minimum yield strength of 50,000 psi, offering greater load capacity

- A992: The current industry standard for structural I-beams, with excellent weldability and consistent mechanical properties

Intsel Steel provides all major grades with full documentation of mechanical properties and mill certifications to ensure your commercial project meets building code requirements.

3. Dimensional Considerations

The dimensions of steel I-beams directly impact their performance characteristics:

- Depth: Greater depth increases vertical load capacity and stiffness

- Flange width: Wider flanges provide better lateral stability

- Web thickness: Thicker webs offer increased shear resistance

- Flange thickness: Affects load-bearing capacity and resistance to local buckling

Standard I-beam sizes are designated by their nominal height and weight per foot (e.g., W10×22 represents a beam approximately 10 inches deep weighing 22 pounds per linear foot). Intsel Steel stocks an extensive range of I-beam dimensions to accommodate virtually any commercial requirement.

4. Span Length and Deflection Limits of Steel I-Beams

The distance an I-beam must span without intermediate support significantly impacts selection:

- Longer spans require deeper beams or higher-strength materials

- Building codes specify maximum allowable deflection (typically expressed as a fraction of the span length)

- Different applications have different deflection tolerances (e.g., supporting a glass curtain wall versus general structural framing)

Our experienced sales representatives can help calculate the appropriate I-beam size to achieve optimal performance across your specific span requirements.

5. Connection Requirements

How I-beams connect to other structural elements affects selection:

- Bolted connections: May require specific flange and web thicknesses

- Welded connections: Necessitate materials with appropriate weldability

- Moment-resisting frames: Often require heavier sections with wider flanges

- Simple connections: Allow for more flexibility in beam selection

Intsel Steel provides complementary connection materials and can recommend the most efficient connection solutions for your I-beam applications.

6. Environmental Considerations

The environment where I-beams will be installed introduces additional selection factors:

- Exposure to moisture or corrosive elements: May require protective coatings or corrosion-resistant grades

- Fire protection requirements: Building codes mandate specific fire ratings for structural steel

- Thermal considerations: Extreme temperature variations may affect performance

- Exterior applications: Often require weathering steel or galvanized finishes

Our product specialists can recommend appropriate protective treatments based on your project’s specific environmental conditions.

7. Budget and Cost Optimization

While structural integrity should never be compromised, cost considerations play a legitimate role in I-beam selection:

- Material efficiency: Using the optimal beam size rather than overengineering

- Availability: Stock items versus specialty orders can impact both cost and timeline

- Fabrication requirements: Some beam types are more economical to modify than others

- Transportation and handling: Larger sections incur higher logistics costs

Intsel Steel’s inventory management and logistics expertise help optimize your steel package for both performance and cost-effectiveness.

Special Considerations for Using Steel I-Beams in Commercial Applications

Different commercial construction types present unique I-beam selection challenges:

Multi-Story Office Buildings

- Requires careful consideration of floor vibration control

- Often benefit from composite beam construction (steel beams working in conjunction with concrete floors)

- May use cambered beams to counteract deflection under load

Retail Spaces

- Typically demand open floor plans with minimal columns

- May require heavier I-beams to support longer spans

- Often need consideration for future reconfigurations

Industrial Facilities

- Frequently support heavy equipment and dynamic loads

- May require enhanced corrosion protection in manufacturing environments

- Often involve crane runway beams with specialized requirements

Healthcare Facilities

- Must address stringent vibration control for sensitive equipment

- Require consideration for future technology integrations

- Often need coordination with complex MEP systems

The Intsel Steel Advantage

As a leading supplier of structural steel, Intsel Steel offers several advantages for commercial projects:

- Extensive inventory of standard and specialty I-beams

- Value-added services, including cutting, drilling, and custom fabrication

- Technical expertise to help select optimal beam specifications

- Quality assurance with full material traceability and certification

- Logistics support for timely delivery to job sites

Steel I-Beams at Intsel Steel East

Selecting the right steel I-beams for commercial construction involves balancing numerous technical factors with practical considerations. By partnering with Intsel Steel, you gain access to both premium structural products and the expertise needed to make informed decisions. Our commitment to quality, combined with decades of industry experience, ensures your commercial construction project will have the robust structural foundation it requires.

For personalized assistance with your next commercial project, contact Intsel Steel’s structural specialists, who can guide you through the entire process from specification to delivery.