5 Benefits Of I Beams Construction

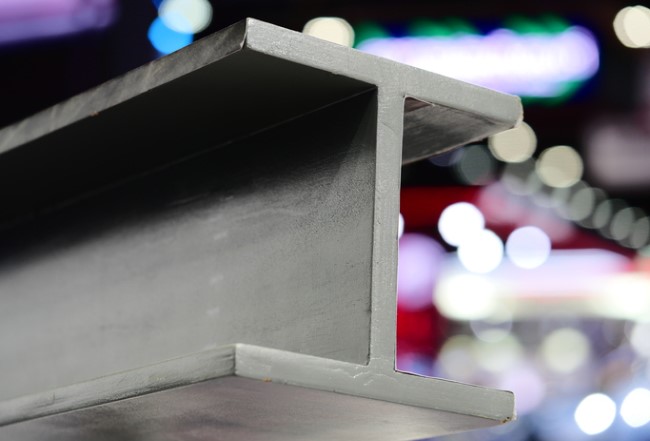

Have you ever wondered how engineers manage to keep such massive buildings standing? There is one useful building structure that if it were not there, the entire building system might collapse. This structure is known as an I beam.

Since they can sustain a large amount of weight from various directions, I beams are important structural steel components used in civil engineering and building construction for steel-framed projects like floor joints and truss systems. When compared to concrete, I beam construction increases the interior space by more than 5% while lowering the building’s load by 19% to 31% and minimizing the structural internal stress.

So, why are the I beams preferred more compared to the wooden beam framework? Is it because of their strength? Are they cost-effective? Continue reading to find out the answers.

1. The Strength of the I Beam

I beams are often manufactured from an iron-steel alloy, but some are also made of aluminum. The method by which steel is melted has a beneficial impact on its strength.

Steel has a property that enables it to endure large amounts of weight. The I beam’s design is intended to distribute weight evenly to the entire beam. When substantial weight is applied to the beam, the deflection will fall near the center, increasing the stress on the sides. It also bends instead of buckles when subjected to intense pressure, making it stronger than other beams.

Most contractors consider using wooden beams because of the flexibility they provide, as they will allow you to drill holes, hang lights, and attach things without compromising the wood’s structure. Drilling holes in an I beam, on the other hand, reduces its structural strength.

Depending on your requirements, both timber beams and steel beams might be beneficial. However, the I beam is always the strongest.

Other qualities of the I beam are high accuracy, low residual stress, and less expensive welding materials, which save approximately 30% of the cost of steel structure construction.

2. Cost-Effectiveness

Cost is crucial in construction projects, and most individuals are looking for ways to reduce construction expenses. You may simply estimate the cost for your project based on the amount of material needed and the building structure.

Considering using I beams in your building project is an important step toward minimizing construction expenses. There are several benefits of using I-beam construction structures in your building projects.

The structure of the building will be sturdy, with minimal components. Building with fewer components will result in cheaper construction costs due to decreased material and shipping expenses.

Because less material will be used in building, the I-beam cost will be low, project completion time will be shortened and as a result, construction costs will be kept to a minimum.

In that case, using the I beam will assure a cheap construction cost. As a result of fewer building materials used, the inside of the structure will be spacious. Also, because of their strength, I beams can span a big area with little support.

3. Design of the I Beam

The designs of the I beams, as well as the materials used in their manufacturing, are the key reasons why they can sustain a lot of weight. A steel I beam is made up of two long planes called flanges and an intermediate part called a web. The cross-section of the web and fridges has an “I” and an “H” appearance due to the shape of the web and flanges.

Depending on their uses, I beams are available in a variety of flange widths and web thicknesses. The axil fiber, which carries the majority of the weight in an I-beam, contains the majority of the material. The shape of the I-beam is critical in increasing resistance to high stress.

The best I beams have a small cross-section area and use less material while maintaining their intended shape. A contractor must consider various aspects when selecting an I-beam, which include:

• Vibration

Certain mass and rigidity are chosen to prevent floor vibration.

• Bend

An I-beam’s cross-section must be strong enough to withstand yield stress.

• Buckling

The flanges are protected to avoid shear locally, or sideways buckling.

• Tension

The contractor should select an I-beam with a web thickness that can withstand high stress without buckling or rippling.

• Deflection

To withstand distortion, the contractor should use a thick I-beam.

4. Durability

Steel is extremely durable because it can endure severe weather conditions. It is even regarded as the most long-lasting construction material. Steel I-beams, unlike wood, are not prone to rotting, aging, mildew, or termites.

The most significant challenge that a building might have is wearing as it ages, which is exacerbated by corrosion.

The advantage of using I beams is resistance to corrosion, making them appropriate for use in both outdoor and interior constructions. As steel beams age, they will not be subjected to wrapping, splitting, fracturing, or creeping.

The important factor that ensures the I-beam’s durability is that it must adhere to rules and regulations set throughout its manufacturing process before it is marketed.

5. Adaptability

I-beam construction eliminates the need for load-bearing walls. Without the need for these support structures, you can design buildings with large spans, walls of windows, or any other design element you choose. Without the restriction of load-bearing walls, you are limited only to your imagination.

I-beams are not just installed in new buildings; they can be used to strengthen, remodel, or enlarge a structure. An I beam in construction is easier to adapt to a new structure since it is easily modifiable. Because of the lower strength, wooden beams are not adjustable.

I-beams are the most cost-effective replacement for a worn-out wooden beam. As a result of trees of the same species having varying grain density, steel I-beams are better compared to wooden beams.

The Choice Is Yours

Using I-beams as part of the construction process opens up many options that are not available with traditional construction.

I-beams allow you to avoid the need for load-bearing walls, which add material and construction time, both of which drive up prices. I-beams allows you to control costs without sacrificing strength or durability, which are the two attributes often compromised when attempting to rein in costs.

Regardless of the project you have in mind, I-beam construction provides uncompromising strength. The production method used to create I-beams leaves you with a sturdy beam that allows for the even distribution of weight. Even in situations where it is undersized for the project, an I-beam will bend, rather than collapse.

Of course, initial building costs are only one part of the cost of a project. With I-beam construction, you can be confident that your building is here to stay. Able to withstand extreme weather conditions, termites, mildew, and other elements that attack buildings over time. Suitable for both outdoor and indoor building projects, I-beams give you freedom and the confidence to build the project as you envision it, without being tied to many of the limitations of traditional construction.

With the understanding of what is an I beam and its uses in I beam construction projects, you may confidently purchase them for any building project. But before you begin, you must consult an expert to ensure that you acquire the correct beams. This will guarantee that you construct a structure that can endure all external stresses without buckling.

If you seek to purchase I beams, allow Bushwick Metals to take care of your bulk I-beam needs for your construction project. Request a quote today and we will provide perfect I beams for your construction on schedule and in a professional way.