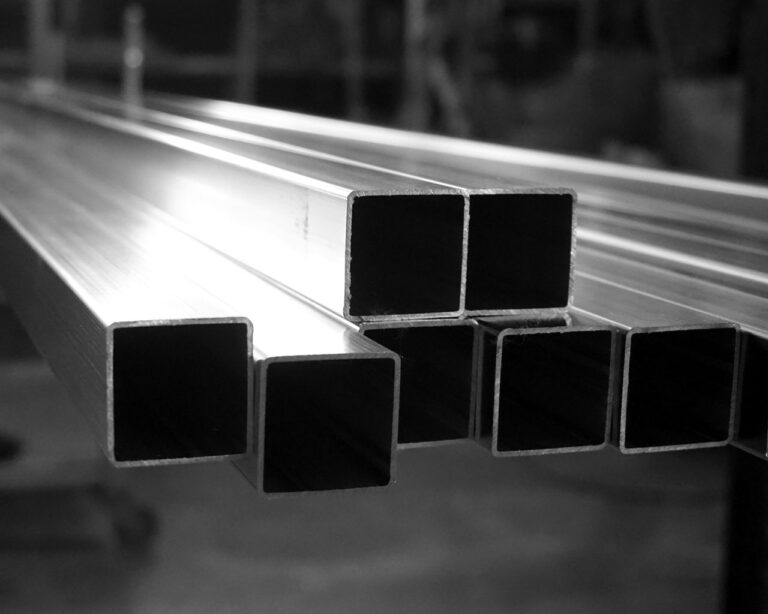

A Closer Look at Square Steel Tubing: Materials That Make a Difference

Materials play a pivotal role in the outcomes of engineering, fabrication, and construction projects. Square steel tubing, in particular, stands out as a versatile material with a broad spectrum of industrial uses. It provides dependable solutions for structural frames and support systems across manufacturing, construction, and beyond. Fabricated from various materials, including alloy or carbon steel, steel tubing is a preferred choice for its durability, resistance to corrosion, and adaptability, making it an exemplary building material.

Understanding Square Steel Tubing

Square tubing not only enhances strength over other structural shapes but also provides a superior strength-to-weight ratio and an aesthetically pleasing look. This makes it a prime choice for commercial construction projects, including trusses, bleacher frames, railings, and columns. For high-pressure environments and mechanical or structural assemblies, carbon steel variants offer exceptional durability and resilience. The ASTM A513 steel tube, known for its cost-effectiveness and versatility, is ideal for a variety of construction projects and product manufacturing.

The broad spectrum of steel tubing applications showcases its crucial role in both manufacturing and architectural design. In the manufacturing sector, square tubing is indispensable for material handling equipment, machinery frames, and conveyor systems, thanks to its robustness and sleek appearance. In contemporary architecture, its clean lines and modern look are sought after for creating balusters, railings, and bar grating stair treads, underscoring its versatility and aesthetic appeal.

Types of Square Steel Tubing

Steel tubes are some of the most versatile and widely used construction materials. They come in a variety of types, each with its own advantages and disadvantages. Here are some of the most common types of steel tubes:

Carbon Steel

Carbon steel, the most common type of steel used in pipes and tubes, offers an optimal blend of affordability and durability. Through the process of heat treatment, which involves controlled heating and cooling, its properties can be significantly enhanced. This treatment can increase the steel’s hardness, strength, or ductility. Despite its many benefits, carbon steel’s major limitation is its vulnerability to corrosion. Typically, carbon steel pipes are utilized in low-pressure environments, functioning as conduits for water and gas lines.

Alloy Steel

To enhance its performance, carbon steel is fortified with alloying elements like nickel, chromium, molybdenum, and manganese. These additions can significantly increase the steel’s strength, corrosion resistance, and heat tolerance. As a result, alloy steel pipes boast a broader spectrum of applications compared to their carbon steel counterparts, serving critical roles in high-pressure pipelines, oil and gas conveyance, and boiler tubes.

Stainless Steel

Stainless steel is a type of steel that has been enhanced with chromium to resist corrosion. It is a good choice for applications where the pipes will be exposed to moisture or chemicals. Stainless steel pipes are used in a wide variety of applications, including plumbing, food processing, and chemical processing.

Galvanized Steel

Galvanized steel is carbon steel that has been coated with a layer of zinc. The zinc coating helps to protect the steel from rust and corrosion. Galvanized steel pipes are a common choice for plumbing applications.

Square Steel Tubing Performance Factors

Steel tubing is available in a wide range of options and specifications, encompassing ultimate tensile strength, minimum yield strength, and minimum elongation before failure. These critical factors significantly impact their performance.

Material Composition

Steel is grouped into different types, each with different properties. The purity level and material of steel affect its quality, depending on what you intend to use it for. When welding, low-quality metals can fail at high temperatures and result in defects. For the best results, a desirable material should have metallurgical properties like shielding gas composition and heat input.

Square Steel Tubing Manufacturing Processes

The manufacturing process involves raw material preparation, welding, and straightening. Steel tubings must undergo multiple fine processing links to ensure the stability and reliability of the final output. Surface treatments like painting, galvanizing, and pickling can improve corrosion resistance and aesthetics.

Considerations for Material Selection

When choosing materials for your square tubing, it is crucial to take several factors into consideration, such as:

Mechanical Properties

Depending on the intended application, the load-bearing capacity and required strength are crucial when choosing a tubing material. Determine what level of flexibility is needed so that your tube can bend without fracturing. Additionally, the hardness of the material can ensure that the tube withstands deformation over time.

Corrosion Resistance

If you are carrying out your project in an environment exposed to moisture and chemicals, the material you choose should withstand these conditions. Materials like carbon steel can be galvanized to make them corrosion-resistant.

Cost Considerations

Your budget determines the type of steel tubing material you can afford. To optimize your budget, consider the material costs, including fabrication and finishing process costs. Stainless steel is corrosion-resistant and aesthetic but more expensive than carbon steel.

Innovations in Square Steel Tubing

The steel industry is the backbone of global construction and manufacturing. Technological changes and global economic fluctuations have affected it in recent years. However, moving towards the future, some emerging trends influence steel tubing production, including:

Sustainable Practices

Steel companies are implementing eco-friendly production methods to reduce carbon emissions. Some strategies involve recycling materials used in production, finding sustainable power sources, and using carbon capture and storage techniques.

Technological Advancements

The emerging technological advancements continuously increase efficiency and streamline operations. The steel industry uses advanced monitoring sensors and automated robotic systems to consistently produce high-quality steel products.

Value-added Services

When you source your square steel tubing from Instel Steel East, be aware that we provide a range of value-added services, including precision cutting, bending, straightening, and customizations tailored to your unique requirements. We also offer delivery of our steel products to many places in the Northeastern United States.

Find the Perfect Square Steel Tubing

The versatility of square steel tubing demands careful selection to ensure your project benefits from both strength and durability, as well as the desired aesthetic appeal. Choosing the right materials is essential for a successful project and visually pleasing results. Contact Intsel Steel East for exceptional steel solutions and discover the finest steel products for your various projects.