Differences Between Raised vs Flat Expanded Metal And Where To Get Both

Did you know that steel buildings and infrastructure have a lifespan of up to 100 years? Steel is the most commonly used metal in today’s world, and that is largely because of its durability, strength, and versatility. Anywhere that you go in the world you will be surrounded by buildings and items made of steel.

There are 3,500 different grades of steel for a variety of applications, so knowing the difference between raised vs flat expanded metal is important for finding the right fit for your construction project. Steel has made building projects simpler and more durable than ever before, and with good reason. Whether your next project requires raised steal or flat expanded steel, there’s a perfect option for what you need.

Keep reading to learn about raised vs flat expanded metal, and the pros and cons of each.

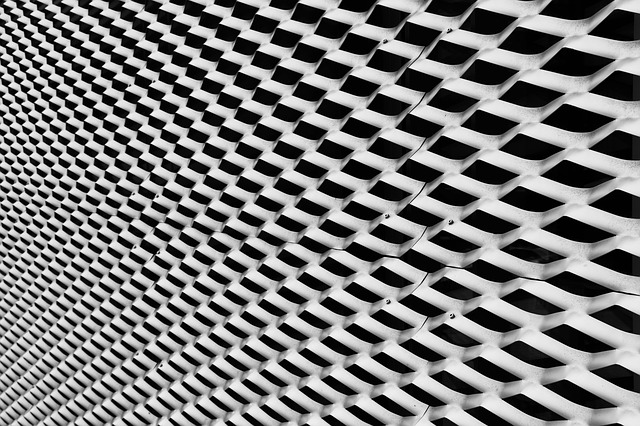

Raised vs Flat Expanded Metal

There are 3,500 different types and grades of steel on the market today, but this article will focus on two types: raised metal, and flat expanded metal.

Both types of metal have their pros and cons, so it is important to learn about what each brings to the table so that you choose the right type for your project:

Raised Expanded Metal

Raised metal, also known as standard metal, is a steel product used for anything from fences to grates. It’s called standard metal because its final form is exactly how it is when it leaves the expanding press.

The strands on raised metal have horizontal angles. making a less smooth surface. The characteristics of each sheet are customizable depending on the pattern size and the amount of expansion applied. Despite the customizable size and thickness of the sheet, the holes and the strands around them are uniform in size and thickness.

Some of the primary applications of raised metal are fences, walkways, and grates. The reason that raised metal is coveted for these purposes is because it is durable and strong. The small openings also allow for air, liquid, and light to pass through. It acts as a strainer by allowing those things to pass through while stopping large objects.

Some other standard uses for the raised expanded metal are for use in lockers as walls and doors to close off areas of warehouses.

Pros and Cons

Raised metal is structurally stronger than other types of expanded metal. The strands distribute a load of weight more evenly, allowing the expanded metal to support more weight than flat expanded metal can.

Additionally, because of the angled strands, raised expanded metal provides more grip and makes them skid resistant for anyone walking on them. This makes them a great option for walkways. Because they come from steel, raised expanded metal is very durable and will last a long time. This means it will save you money because you won’t need to pay for repairs or a replacement for 40 or more years.

Some cons of raised expanded metal are that it is not as aesthetically pleasing as flat expanded metal. It is also heavier and denser, which can cost you more to have it delivered.

Flat Expanded Metal

Flat expanded metal is made the same way that raised expanded metal is, with one difference in the process. After exiting the press it is milled to make a smooth and flat surface. By removing the ridges of standard or raised expanded metal, it gives the stainless steel expanded metal a much sleeker appearance.

Compared to raised expanded metal, flat expanded metal is thinner and flatter. It is most useful where abrasion isn’t as important and aesthetics are more valuable. Removing the ridges also makes flat expanded metal weigh less than raised expanded metal. It also has a finished surface to make it look even more aesthetically pleasing.

Some typical uses of flat expanded metal are fencing, use for enclosures and safety areas, and even walkways on billboards. It can also make great railings, gates, paths, and grates.

Pros and Cons

The big pro of flat expanded metal is that it weighs less. Because it weighs less, it costs less to transport and manufacture. It can save you money by opting to go with flat expanded metal.

It also has a distinctive finish that sets it apart from raised expanded metal. If the grip is less important than appearance for what you need the expanded metal for, flat expanded metal will be a better fit for you.

Similar to raised expanded metal, flat expanded metal is great for letting light, air, and water through it while still presenting a barrier to larger objects. It is also a very strong and durable material for whatever application you are using it for. Corrosion won’t be an issue either since it is made from stainless steel and coated to protect it from the elements.

Some cons of flat expanded metal are that you don’t have as good of grip in wet conditions if it is used as a walkway. It also isn’t as strong as raised expanded metal due to being flattened out and stretched.

Ultimately, flat expanded metal looks much nicer and is less expensive but it isn’t as utilitarian as the raised expanded metal alternative.

Choosing the Right Expanded Metal for You

No matter what your application or project is, when it comes to raised vs flat expanded metal there is an option that will suit your needs. Whether it is walkways or fencing, or even decorations, expanded metal is a perfect option for you.

Knowing which option fits you best is a key component to ensuring that your project is completed to your satisfaction. Intsel Steel and Bushwick Metals have both raised and flat expanded metal for your next project. Contact us to find the expanded metal that you’ve been looking for in your project needs.